Application and advantages of silicone dispensing machine in high-precision manufacturing

Understanding the Role of Silicone Dispensing Machines in Precision Manufacturing

Silicone dispensing machines play a vital role in manufacturing processes where precise application of silicone is needed. Most models come equipped with storage tanks, nozzles, valves and pumps that have been carefully adjusted for accuracy. When these parts work together properly, they can apply silicone exactly where it needs to go on different materials. This matters a lot when making things like rubber seals for electronics, heat resistant kitchen utensils, children's bath toys, and countless other items requiring tight tolerances. What makes today's machines stand out is their programming capability. Manufacturers set specific parameters once, and the machine repeats those exact conditions throughout production runs, which means every item comes out looking and performing consistently across thousands of units.

Getting things right down to the last detail matters a lot when it comes to making good products, which is why silicone dispensing machines have become so important in factories today. These devices let manufacturers control how much silicone flows and where it goes with remarkable accuracy, cutting down on wasted materials and speeding up production times. Take silicone phone case manufacturing as a real world example. When applied properly, the silicone only goes where it needs to go on the phone frame, avoiding unnecessary buildup that would otherwise compromise both appearance and function. Manufacturers who invest in these systems often see better yields from their raw materials too. As industries continue pushing toward leaner operations, having machines that deliver consistent results makes all the difference between staying competitive and falling behind.

Advantages of Using Silicone Dispensing Machines

Silicone dispensing machines really boost production efficiency when they cut down on wasted time and keep things moving smoothly through automated processes. When repetitive tasks get handled automatically, there's less room for mistakes made by tired workers, which means production lines run much better overall. Take those big factories making thousands of silicone gaskets every day as a good case study. With these machines running nonstop, operators don't have to constantly stop and start operations or jump in manually all the time. The result? Faster turnaround times and products coming off the line looking exactly the same each time. Manufacturers love this because it saves money in the long run while keeping quality standards high across different batches.

These machines really help boost product quality because they keep things consistent when applying silicone materials throughout production runs. Built to deliver just the right amount of silicone every time, they stick closely to those tight specifications needed in so many different manufacturing settings. Take automotive gaskets versus detailed designs on mobile phone cases for instance the same machine handles both with remarkable accuracy. What this means practically is that products come out looking and performing the same way batch after batch. For manufacturers trying to stand out against competitors, having such reliable output makes all the difference in customer satisfaction and repeat business orders.

When it comes to saving money, silicone dispensing machines really pay off in the long run. Factories using these systems see much less waste because they apply exactly what's needed for each job. No more guessing games or overusing expensive materials. The machines just put down the right amount every time. Plus, these dispensers last forever basically. We've seen some units still running strong after years of constant use, so there's hardly any need for repairs or replacements. For small to medium sized manufacturing operations trying to improve quality while keeping expenses under control, investing in a good silicone dispenser makes all sorts of sense financially.

Key Applications of Silicone Dispensing Machines

Silicone dispensing equipment plays a major role in making consumer goods, speeding up production across many different product lines. Take the toy business as one case study these machines put on those soft silicone handles that make toys safer for little hands while also lasting longer through rough play sessions. When it comes to kitchen items, manufacturers rely on them to craft detailed patterns and apply those special non-stick surfaces onto baking molds made from silicone. Without this technology, companies would struggle to meet what shoppers demand today both in terms of how long things last and how good they look sitting on store shelves next to competitors' offerings.

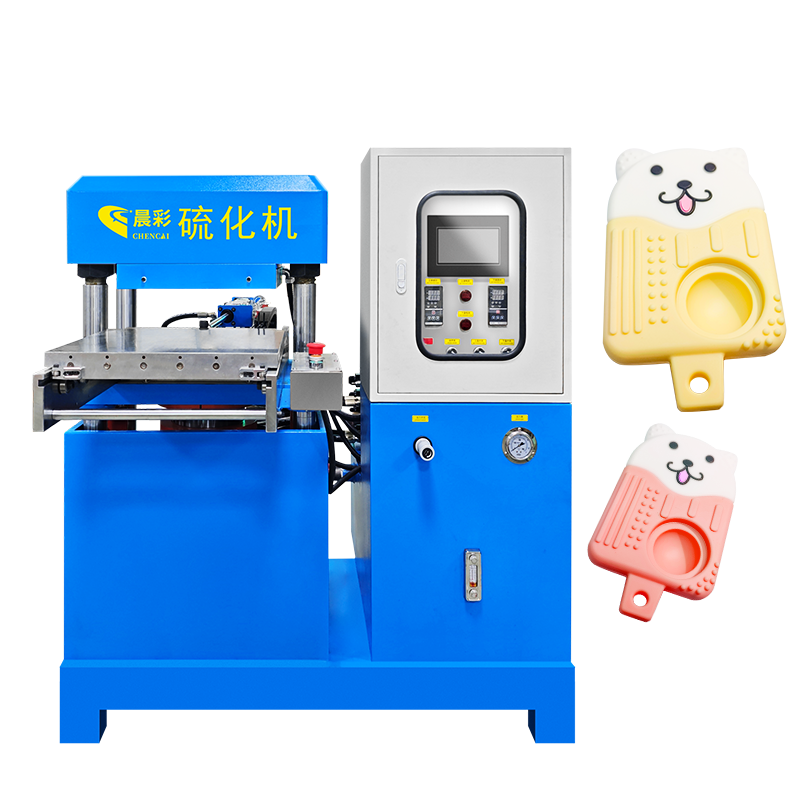

Silicone dispensing machines play a vital role in the automotive manufacturing process when it comes to sealing and insulating various components throughout vehicles. These machines accurately apply silicone gaskets and seals that stop fluid leaks and improve resistance against high temperatures. Car makers rely on them regularly to produce essential parts such as silicone hoses and vibration dampers, all of which need to perform reliably under tough conditions. The consistent way these machines work allows factories to maintain their quality standards without compromising safety or durability requirements during production runs.

Silicone dispensing machines have become essential tools in electronics assembly during potting and encapsulation work. These machines shield delicate electronic parts against water damage, dirt buildup, and mechanical shocks that could otherwise ruin circuits. When applied correctly, they coat entire circuit boards thoroughly so nothing gets left exposed. For gadgets like smartphones that need to last through daily wear and tear, this kind of protection makes all the difference. Beyond just making production faster, these machines actually improve how well electronic products hold up over time. Manufacturers report fewer warranty claims and better customer satisfaction when their devices get proper encapsulation treatment.

Types of Silicone Dispensing Machines

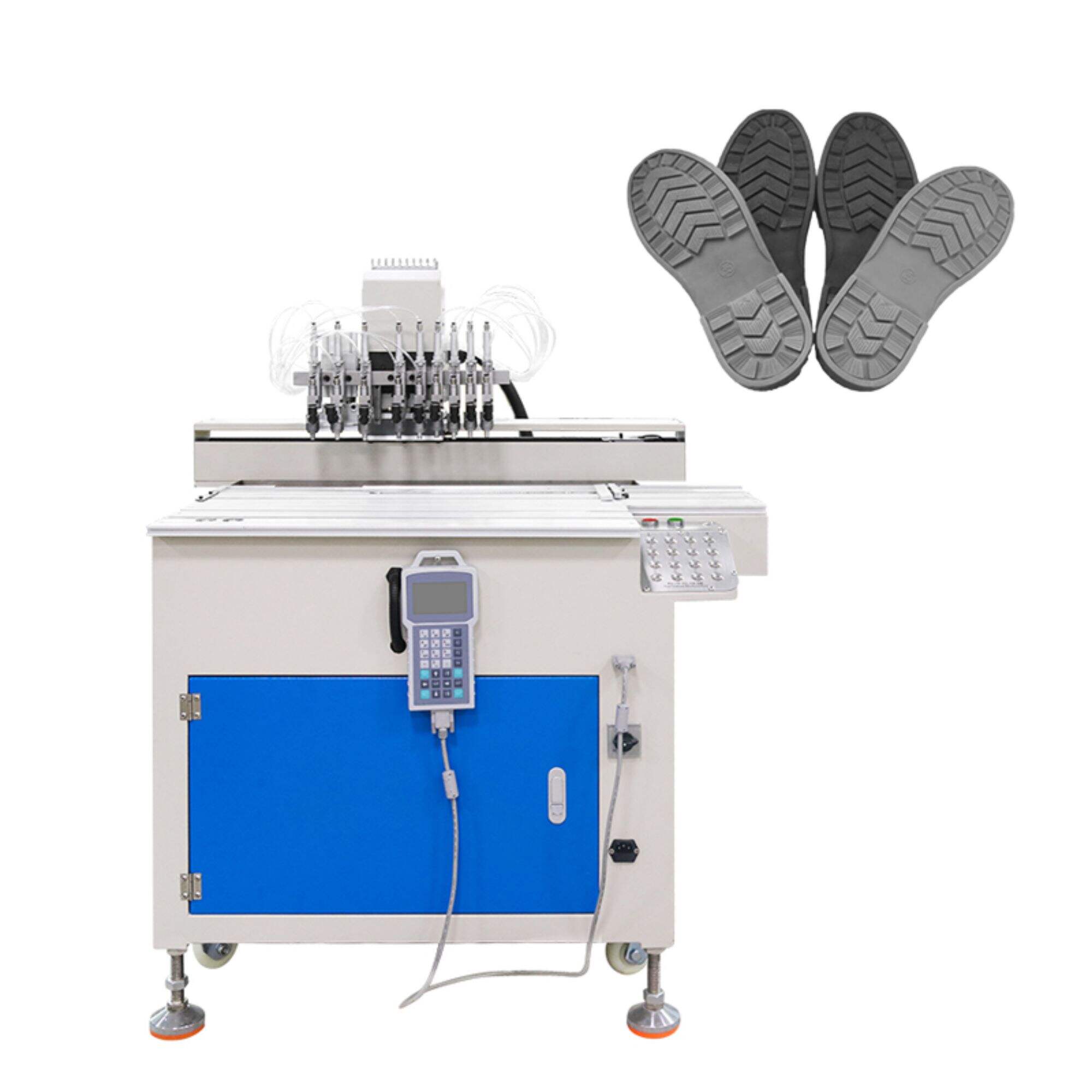

There are several different kinds of silicone dispensing machines out there, each built for particular tasks around the shop floor. The desktop model stands out among them because it takes up so little space on workbenches. Great for smaller operations where room is at a premium, these units fit right into corner spaces without hogging valuable real estate. Crafters working on intricate jewelry pieces love them since they can get really precise with those tiny mold details. Most models feature control panels that aren't too complicated to figure out, letting operators tweak settings until they hit just the right consistency. And since they don't weigh much and don't need special installation, both weekend tinkerers and local business owners find them pretty handy to have around.

Industrial silicone dispensing machines play a key role in big manufacturing setups. Most models come with sizable reservoirs ranging from 50 to 200 liters, which means they can keep running nonstop during production shifts. This matters a lot for sectors like car manufacturing and electronic assembly lines. Modern machines have all sorts of automated features these days, from touch screen interfaces to programmable settings that let operators set up intricate dispensing patterns for thousands of parts at once. Factory managers really appreciate this when making things like silicone seals for engines or precision components used in medical equipment. When connected properly to existing factory infrastructure, these systems cut down on wasted time and materials while maintaining consistent product quality across entire batches.

Featured Silicone Dispensing Machines

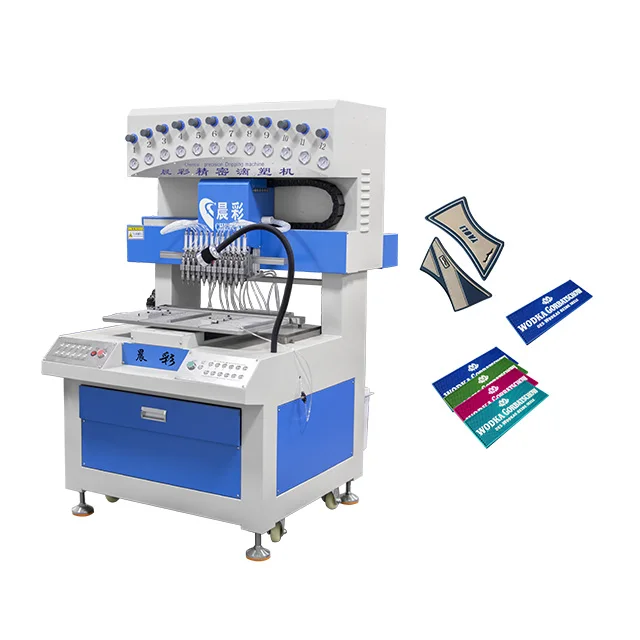

The 12 Colors Silicone Dispenser for PVC Keychains has become pretty popular across different sectors including promotional goods and accessory manufacturing. What makes this machine stand out is its large work area combined with precise movement control along all three axes, so it handles detailed jobs without issues. One big plus is that operators can work with several colors at once during production runs, cutting down on setup time and streamlining the whole process. Speed matters too when running these machines day in and day out. The injection system works really well even under demanding conditions, which explains why many factories incorporate them into their more complicated manufacturing setups where consistency counts.

The Enlargement Style 18 Colors PVC Silicone Dispenser really shines when it comes to handling bigger volumes and working faster than most competitors on the market today. What sets this machine apart is its ability to handle all those different colors without missing a beat during each run. Manufacturers in fields where getting things right matters a lot find this equipment especially useful. Think about places like electronic component factories or textile plants where small mistakes can cost big time. Speed doesn't come at the expense of quality either. Many businesses report being able to ramp up their production significantly without sacrificing the standards they've built their reputation on over years of operation.

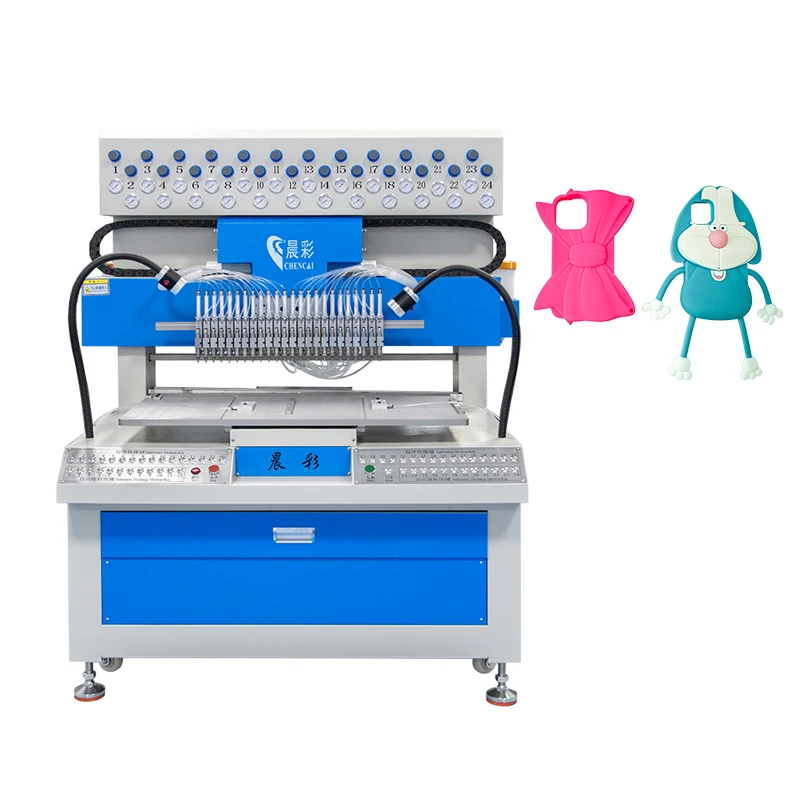

The Soft PVC Silicone Dispensing Machine that handles 24 different colors stands out because it works well in so many fields from electronics manufacturing right down to making car parts. What makes this machine special is how it can handle several colors at once without missing a beat, which really boosts productivity while still maintaining great quality in the final product. For anyone working on intricate designs that need lots of color variation, this equipment becomes indispensable. Companies save money too since fewer workers are needed to manage the process compared to traditional methods. Many shops report cutting their production time nearly in half after switching to this system.

Conclusion: The Future of Silicone Dispensing Machines in Manufacturing

Silicone dispensing machines seem poised for big things in manufacturing thanks to all sorts of tech improvements happening right now. We're seeing some pretty cool developments lately like better automated systems, super accurate control mechanisms, and equipment built with green principles in mind. What makes these advances so exciting is how they actually change what manufacturers can do day to day. Factories gain much more freedom in their production runs while wasting far less material than before. Some newer models come packed with AI features too. These smart machines can basically tell when parts need replacing or figure out exactly how much silicone should go where during each cycle. This means fewer unexpected breakdowns and way better overall productivity for shops running these systems.

Manufacturing efficiency gets a real shot in the arm from these machines. Looking ahead, new generation silicone dispensers promise faster production lines while delivering better quality products across multiple sectors. When companies automate those tricky manual processes that used to take hours of skilled labor, mistakes drop off dramatically and payroll expenses start to shrink too. The automotive and electronics industries are already seeing results from this shift. As more factories roll out these smart systems, turnaround times should get shorter, helping businesses keep up with customers who want their orders fulfilled quicker than ever before. Some plants report cutting delivery windows by almost half within months of installation.

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY