Technical development and innovation trend of PVC dispensing machine

Introduction to PVC Dispensing Machines

PVC dispensing machines are pretty much indispensable in manufacturing settings where accurate application of polyvinyl chloride matters. These systems typically come equipped with three main parts: a dispensing head that does the actual work, a control panel for operators to manage settings, plus storage tanks for holding the raw PVC material. When running, the machine measures out just the right amount needed and applies it to whatever surface requires coating. This careful process helps maintain product consistency across batches while keeping production lines moving efficiently without waste.

PVC dispensing machines have become essential tools across many manufacturing sectors. These systems speed up production because they automate how PVC gets applied precisely where needed. Less manual work means fewer mistakes made by workers during repetitive tasks. What's more important for manufacturers is that every single item coming out of these machines looks exactly the same in terms of dimensions and what materials go into them. When products are consistently built this way, customers get items that last longer without breaking down so quickly. Factories save money over time since there's less waste and rework required when everything comes off the line looking good right from start to finish.

Key Benefits of Using PVC Dispensing Machines

PVC dispensing machines are becoming really important in manufacturing because they work so efficiently and can be automated. Looking at various industry reports, it seems clear that when these machines get automated, the time needed for operations drops quite a bit, which means factories can produce more stuff overall. Some real world examples show operation times cutting down by around 30% after installing automated dispensing systems. The main benefit here is that manufacturers can keep up with production needs without having workers constantly monitoring everything. Plus, this setup keeps things running at steady pace most of the time, though there are occasional hiccups when maintenance is needed or unexpected issues pop up during production runs.

Getting the right amount every time is one of those big selling points for PVC dispensing machines. They're built to put out just the right quantity during each run, which means less wasted material overall. Industry reports show that when companies use these precise dispensing systems, they tend to save around 15% on materials. That kind of saving adds up over time while also making sure the final products stay consistent from batch to batch. When parts come out exactly the same size and have uniform properties throughout, it becomes much easier for manufacturers to meet those tough quality requirements customers demand nowadays.

One major advantage of PVC dispensing machines is the money they save in the long run. Sure, buying one upfront costs something, but most businesses find they recoup that expense pretty quickly. These automated systems cut down on labor expenses because there's just no need for someone to stand around watching every single dispensing operation anymore. And let's not forget about all the material that gets wasted when humans handle things manually. We've seen real world numbers where factories implementing this tech typically knock about 20 percent off their production costs within a year or two. That kind of saving adds up fast, especially when looking at monthly profit statements.

PVC dispensing machines bring real value to many different sectors because they're so flexible and able to adjust on the fly. The machines work with all sorts of mold sizes and shapes which means manufacturers can tackle pretty much any production need that comes along. Take the automotive industry for example - companies there have found these dispensers incredibly useful when they need to switch between small batches of specialized parts and larger runs of standard components. Electronics manufacturers similarly rely on this equipment to keep up with fast changing consumer preferences without having to invest in entirely new machinery every time the market shifts. For business owners looking to stay ahead of the curve, being able to respond quickly to unexpected demand changes while keeping costs under control is a major advantage that these versatile machines provide.

Overall, PVC dispensing machines offer a strategic advantage in manufacturing by combining efficiency, precision, cost savings, and flexibilityâvital attributes for maintaining quality and competitiveness in an ever-evolving industry landscape.

Applications of PVC Dispensing Machines in Various Industries

The automotive industry really depends on PVC dispensing machines when it comes to making all those different components and parts we see in vehicles today. These devices make a big difference in how well sealing and bonding work gets done, something that's absolutely necessary if car parts are going to last long enough and perform properly under various conditions. When factories start using these dispensers regularly, they notice their material applications become much more uniform across batches. This matters because it means better overall product quality while also cutting down on how long things take to produce. For auto makers who need every single component to meet strict specifications, having this kind of consistency just makes good business sense in the competitive market place.

PVC dispensing machines are pretty much indispensable in the world of electronics manufacturing when it comes to making circuit boards and other electronic parts. These machines deliver pinpoint accuracy when applying materials, something absolutely necessary given how complex modern circuit board designs have become. What this means in practice is better quality end products plus significant savings on wasted materials during production runs. Manufacturers benefit from both angles actually getting their components right the first time around while keeping costs down through reduced material consumption.

The fashion world has started adopting PVC dispensing machines for some pretty creative stuff. These devices let designers apply materials like PVC patches or fancy decorations onto clothes with real precision. What makes them so valuable is their fast yet accurate dispensing capability, which matters a lot in an industry where trends shift constantly. Garment makers can now produce those special edition pieces customers love without compromising quality. Fashion houses are finding these machines indispensable when they need to balance innovation with production efficiency, especially during busy seasons when demand spikes unexpectedly.

Understanding the Technical Trends in PVC Dispensing Machines

PVC dispensing machines are seeing some pretty impressive tech upgrades lately, mostly thanks to better automation systems. The improvements really boost how precise these machines are, make them work faster, and generally easier for operators to handle day to day. Manufacturers can now streamline their production lines quite a bit because automated systems take care of complicated jobs that used to require constant manual oversight. Take sensor tech for example these days it's much smarter about measuring exactly how much material gets dispensed. These sensors adjust themselves on the fly depending on what application they're being used for, which means less waste and fewer rejected products down the line.

Sustainability has become a major focus across manufacturing sectors these days. Companies worldwide are pushing for greener approaches, including those working with PVC dispensing systems. Many manufacturers are now focusing their efforts on cutting down waste by using materials more precisely while also looking at ways to cut energy costs during production runs. There's growing interest in incorporating components made from recycled plastics and even some biodegradable alternatives for machine parts. This shift isn't just good for the planet it makes financial sense too when considering long term operational expenses and regulatory requirements that keep getting stricter every year.

The future of PVC dispensing tech looks promising with smart machines and IoT integration becoming increasingly common. These new systems let manufacturers monitor operations in real time while making decisions based on actual data instead of guesswork. This leads to better performance overall and helps predict when maintenance will be needed before problems arise. The changes we're seeing don't just save money on operations costs either they give factories much more flexibility to adapt quickly to what customers want right now. Market demands shift all the time, so having this kind of responsiveness makes a big difference. We can already see how companies adopting these technologies are transforming their production lines into something far more efficient than traditional setups ever could manage.

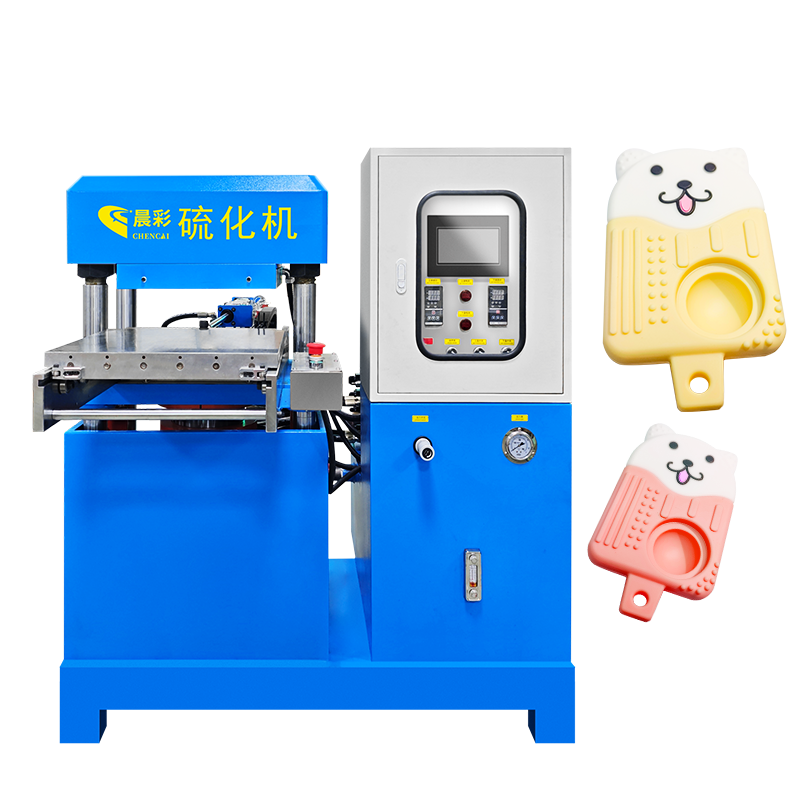

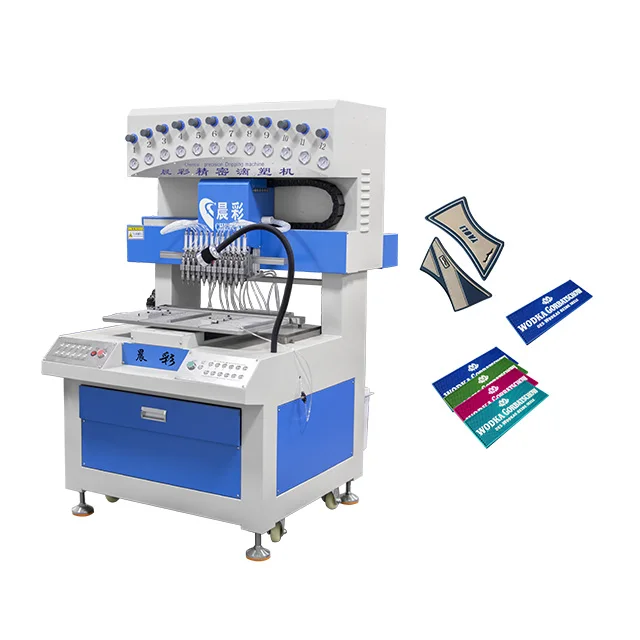

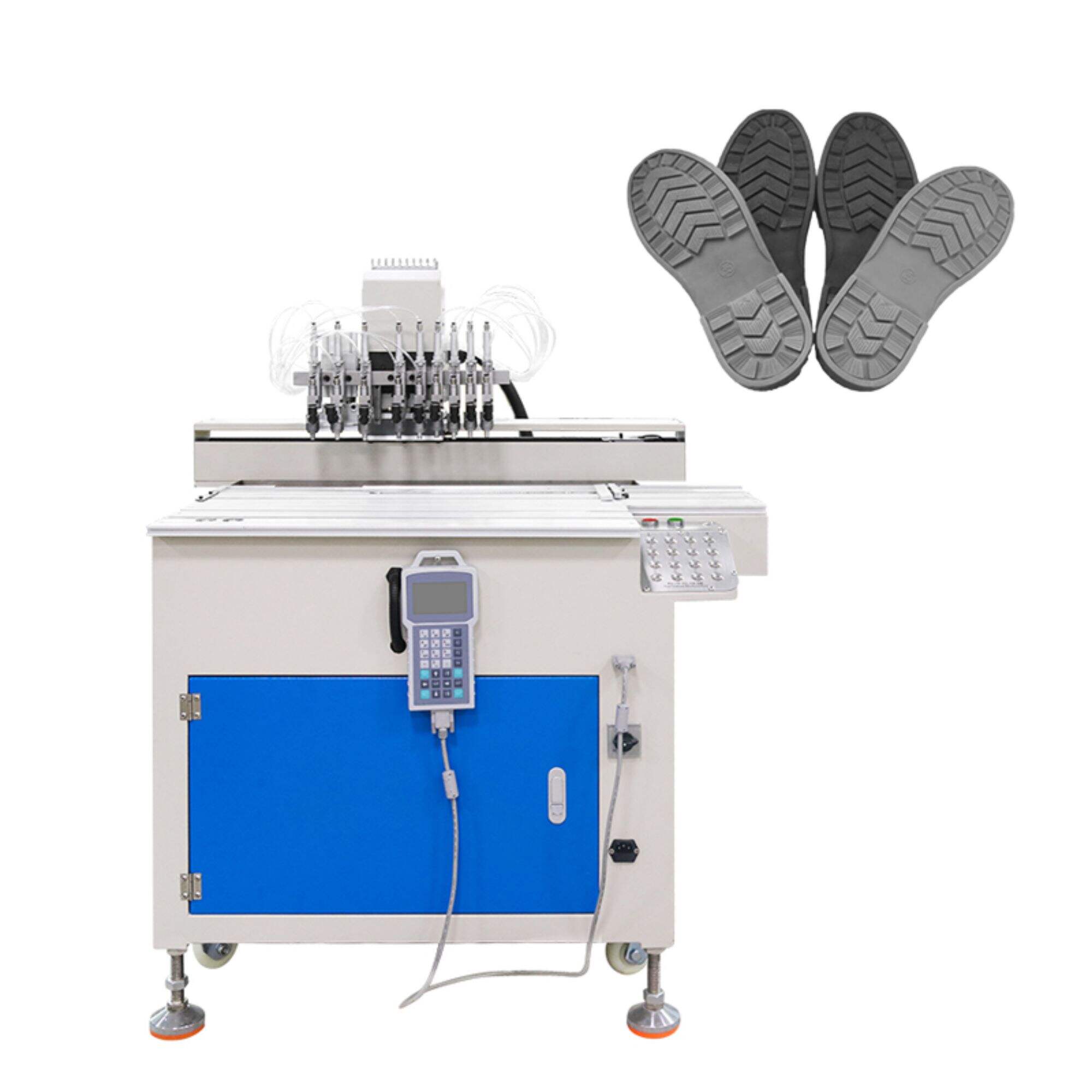

Featured Products: An Overview of PVC Dispensing Machines

Explore a curated selection of PVC dispensing machines designed to enhance productivity and efficiency in various manufacturing processes. These machines stand out for their impressive features and capabilities catering to diverse production needs.

These products exemplify the blend of functionality and innovation crucial for modern manufacturing, ensuring high-efficiency outputs and user-friendly operations.

Conclusion: The Future of PVC Dispensing Machines

In conclusion, PVC dispensing machines have shown significant benefits, including enhancing efficiency, precision, and product quality while reducing costs. As technology advances, the industry is poised for growth, driven by increasing demand and innovation.

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY