Silicone dispensing machine: technical features and industry application analysis

Introduction to Silicone Dispensing Machines

Silicone dispensing machines play a key role across many manufacturing sectors, mainly because they apply silicone materials with remarkable accuracy onto all sorts of products. Most setups include a reservoir for storing the material, plus dispensing systems featuring nozzles, valves, pumps, and often sophisticated control panels that let operators fine tune parameters. The versatility is impressive too - these machines can lay down silicone in straight lines, individual dots, or even cover larger surfaces depending on what's needed for each job. Take automotive manufacturing for instance. When making those rubber seals between car doors and frames, manufacturers rely on machines with specially sized nozzles to create consistent beads of silicone along edges, ensuring proper sealing without excess waste.

Silicone dispensing plays a really important part in manufacturing these days. The machines do wonders for precision work, boost efficiency rates, and keep products looking consistent batch after batch something every manufacturer wants when striving for quality control. When companies automate their silicone application processes, they get much better uniformity across everything made. Think about those detailed phone case designs or the slick non-stick coatings on cookware items nobody likes sticking to pans. Getting this right means faster production runs while cutting down on material waste at the same time. Manufacturers need this kind of reliability to keep up with what customers expect nowadays without breaking the bank on resources.

Essential Components of Silicone Dispensing Machines

Silicone dispensing machines have multiple parts working together to get the job done right and efficiently. At the heart of most systems sits the storage tank or reservoir where all that silicone hangs out waiting to be used. These tanks come in various sizes depending on what kind of work needs doing. Some might need bigger tanks for continuous operation while others can manage with smaller ones for lighter tasks. When manufacturers talk about good reservoir design, they're really referring to something simple but crucial – keeping the silicone flowing without interruption. This matters a lot in factories running non-stop production lines where even a brief stoppage could cause major headaches downstream.

A typical dispensing setup has three main components: nozzles, valves, and pumps. These parts work together to get that accurate silicone placement everyone wants. Let's start with nozzles. They basically decide what shape and size the silicone comes out in. Need thin lines for sealing? Or maybe broader coverage for creating complex patterns? The right nozzle makes all the difference, especially when manufacturing gaskets or detailed designs where precision counts. Then there are the valves. Their job is controlling when the silicone flows and when it stops. Good valve design prevents wasted material while keeping measurements spot on. And finally we have pumps. These bad boys generate the pressure needed to push the silicone through the whole system. Some newer systems even come equipped with servo driven pumps that give operators much finer control over flow rates, something that can really improve product quality in high tolerance applications.

Programmable controls really boost how flexible and efficient silicone dispensing machines become. Operators get to adjust things like how much material gets dispensed, the speed it comes out at, and even the actual pattern shape itself depending on what they need to make. Take decorative silicone phone cases for instance. Without those programmable settings, getting the same intricate designs repeated over and over would be almost impossible. The automated system cuts down on all that manual work that humans have to do, which means fewer mistakes happen during production runs. Plus, every batch ends up looking pretty much identical in quality when everything is properly programmed. Most factories find that adding these kinds of control options makes their whole manufacturing operation run smoother while still maintaining tight quality standards throughout.

Applications of Silicone Dispensing Machines

Silicone dispensing equipment is really important for making consumer goods last longer and look better. These machines work wonders in items like children's toys and household kitchenware where they dispense just the right amount of silicone material for both looks and function. Take silicone baking molds for instance. The dispensing system shapes the silicone material with precision, giving those molds their non stick surface while also creating attractive patterns on the outside. Every single mold comes out looking consistent and meeting quality standards because of this process. Manufacturers rely heavily on these systems to maintain product consistency throughout large production runs.

Silicone dispensing machines have become a must-have tool in the electronics manufacturing world when it comes to protecting components and managing heat issues. The reason? Silicone itself is pretty amazing stuff. It conducts heat well while also acting as an insulator, which makes it great at keeping sensitive electronics safe from both moisture damage and overheating problems. These dispensing systems let factory workers apply just the right amount of silicone around those tiny, fragile parts on circuit boards. What does this mean in practice? Longer lasting products and fewer quality control headaches down the line because everything stays performing consistently over time.

Silicone dispensing machines play a big role in the automotive sector, especially when it comes to things like sealing gaps, sticking parts together, and providing insulation. Car manufacturers use these machines to put down silicone where it matters most - creating solid seals around doors and windows, cutting down on annoying road noise, and protecting sensitive electrical bits from damage. The accuracy of this process makes cars last longer overall while making rides smoother and quieter inside. Drivers notice the difference too, since proper sealing keeps temperatures stable within the cabin and minimizes those pesky rattles we all hate during long drives.

Types of Silicone Dispensing Machines

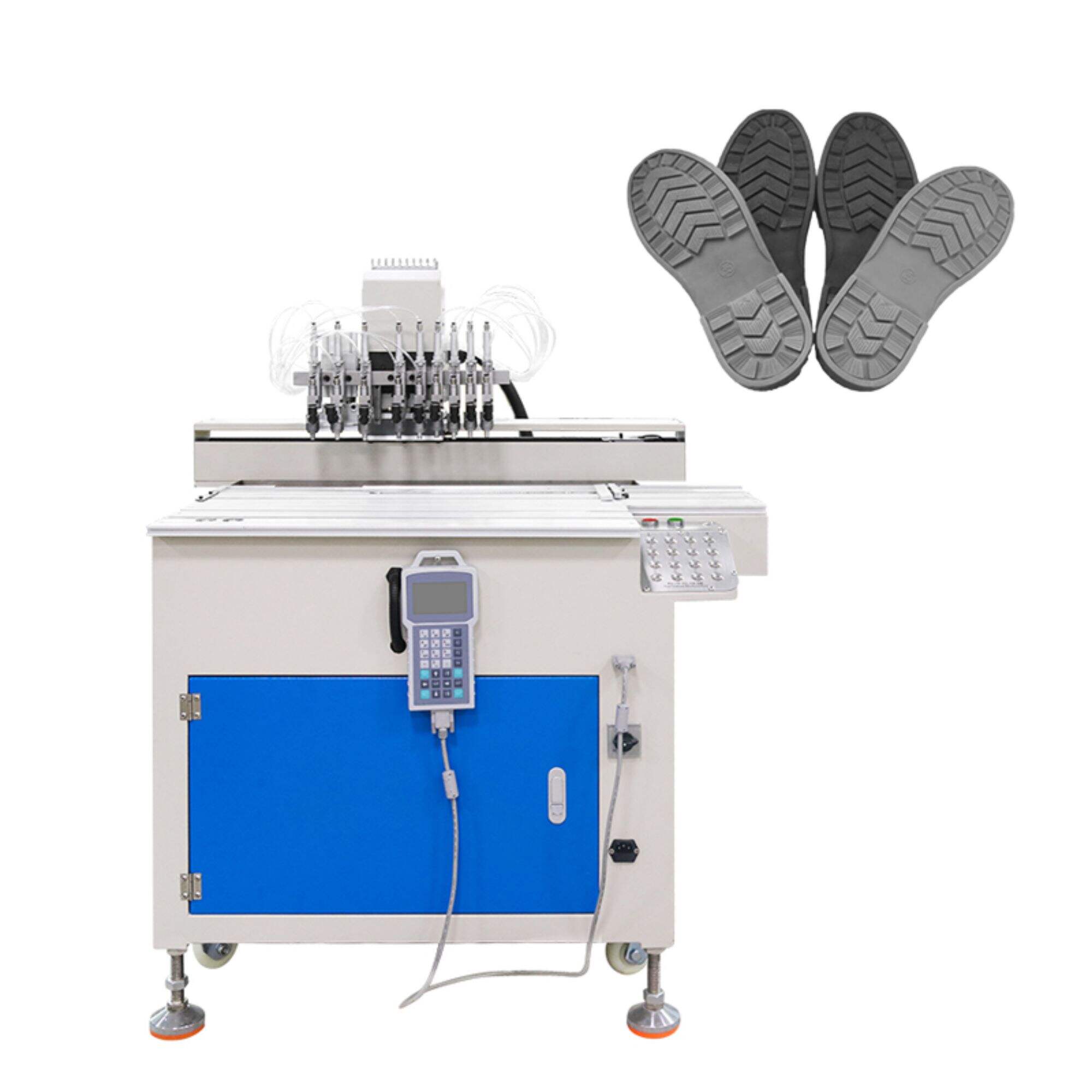

There are several different kinds of silicone dispensing machines out there, built specifically for different manufacturing requirements. The desktop models work great for smaller shops or crafters who need something compact but still accurate enough for their projects. These little machines let businesses create things like intricate jewelry pieces or tiny custom molds without too much hassle. On the other end of the spectrum we find those big industrial units meant for serious factory work. Industrial scale dispensers typically have huge tanks that can hold plenty of material, so they don't need constant refilling during long production runs. Factories rely heavily on these heavy duty machines when running non stop shifts because stopping to refill would just slow everything down way too much.

The latest industrial silicone dispensing machines come packed with features that really boost productivity on factory floors. Most modern units have automated systems capable of handling intricate dispensing patterns over hundreds of parts without missing a beat. Many models now feature massive reservoirs holding up to 50 liters of material, allowing operators to run production lines nonstop for days at a time before needing refills. The automation doesn't stop there either. Conveyor belt integration has become standard equipment on most high-end machines, making it much easier to move finished products off the line while bringing new items into position automatically. These improvements make all the difference in industries where volume matters most, like when manufacturing those rubber seals for car engines or producing thousands of identical silicone baking molds for home kitchens.

What sets high volume dispensing systems apart is how fast they work while still being precise about where the material goes. Most of these machines come packed with advanced tech features that let them dispense silicone quickly without sacrificing accuracy. Even when running at top speed, these systems keep things tight enough so products pass all those tough quality checks manufacturers demand. Another big plus is their flexibility with different types of silicone materials. Some can handle everything from thin liquid formulas to thick pastes, which means factories don't need separate equipment for each job. This versatility explains why we see these systems everywhere nowadays in industries making everything from circuit boards to household appliances.

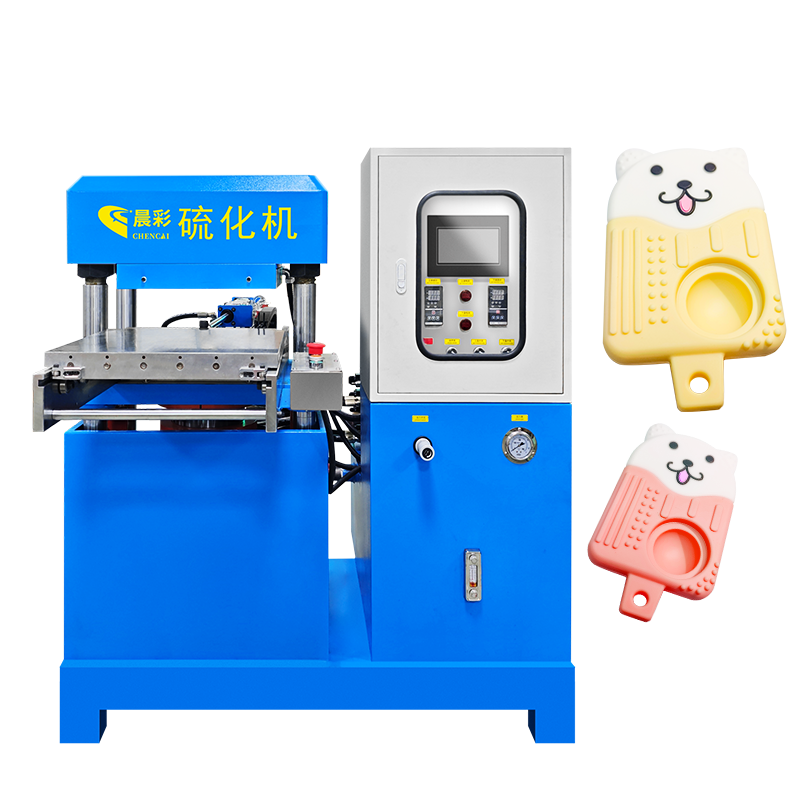

Featured Silicone Dispensing Machines

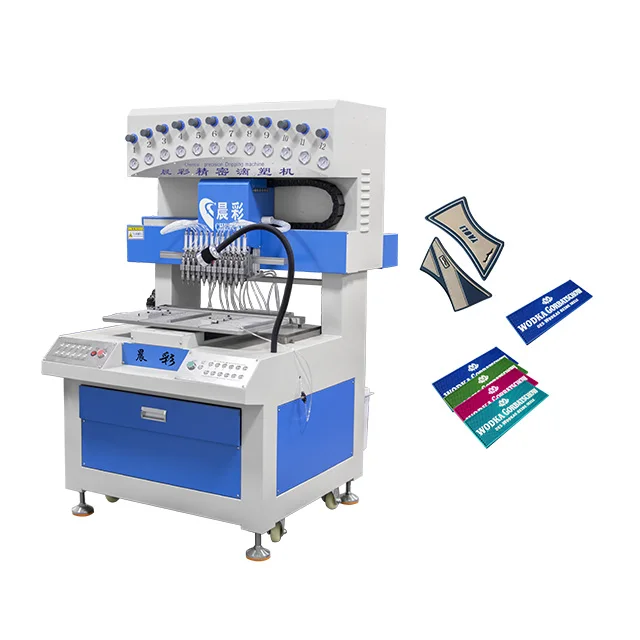

The 12 Colors Silicone Dispensing Machine PVC Keychain Machine has become a favorite among artists and small business owners who create custom keychains. What makes this particular model stand out? It handles those tricky multi-color jobs with real precision, something that matters a lot when customers want unique designs. The whole setup is pretty straightforward to operate too, which means even one person can run several machines at once without breaking a sweat. And let's face it, saving money while getting more done in the shop is always a good thing for anyone running their own business.

When businesses need to boost their production capabilities, the Enlargement Style 18 Colors PVC Silicone Dispensing Machine really shines. What sets this equipment apart is its flexibility to handle intricate jobs involving as many as eighteen different color combinations. Large manufacturing operations across industries such as apparel production, electronic component assembly, and auto parts fabrication find this machine particularly valuable. Manufacturers report not just faster processing times but actual reductions in material waste too, which translates into real money saved month after month on operational expenses.

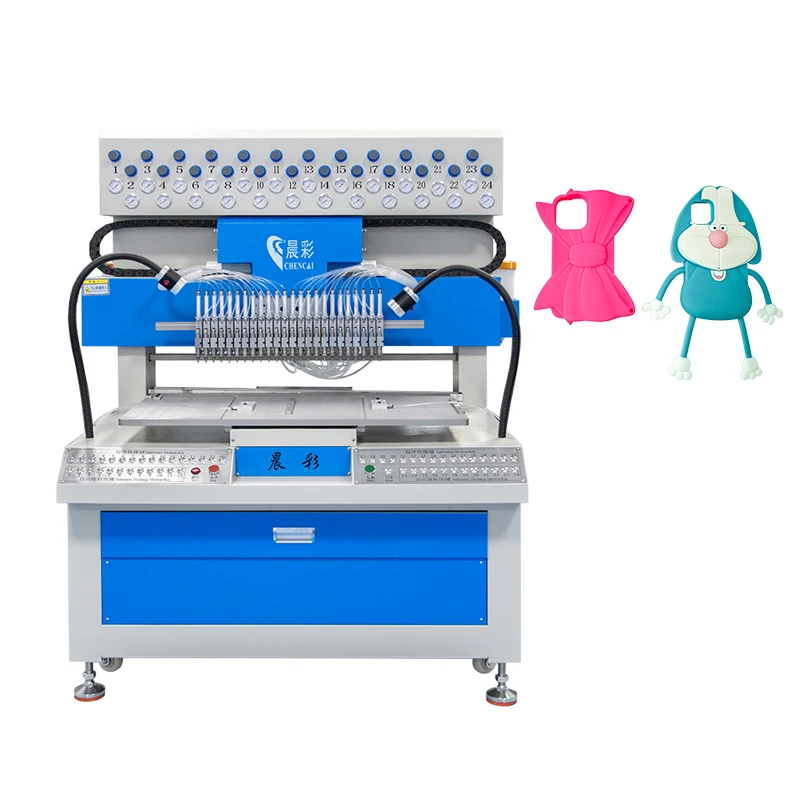

The Soft PVC Silicone Dispensing Machine comes equipped with 24 colors right out of the box, making it ideal for manufacturers who need to create intricate designs with bold color combinations. Built tough with a sturdy frame and plenty of room to work, this machine delivers consistent results time after time. It handles everything from small batches to larger runs efficiently, which is why many companies in the advertising industry and makers of fashion accessories have started relying on it for their production needs. The extra colors open up creative possibilities that just weren't there before.

These machines, with their varied capabilities and functionalities, cater to a broad spectrum of industry needs, providing efficiency and quality in silicone dispensing applications.

Benefits of Using Silicone Dispensing Machines

Silicone dispensing machines really boost how fast things get made while keeping quality consistent across products. When factories install these automated systems, they see big jumps in output numbers. Some shops have told us their production rates went up around 15% after switching to silicon dispensers. Why? Well, these machines handle the same task over and over again without getting tired or making mistakes. They just keep going at the same pace day after day, which means fewer workers needed for monitoring and much shorter time between product cycles. The precision factor alone saves hours on rework and adjustments that would otherwise eat into profits.

Silicone dispensing machines actually do a pretty good job at cutting down on wasted materials something manufacturers care about a lot. Some studies out there show that when factories switch to automated dispensing systems, they tend to waste around 10 percent less material overall. The way these machines work means they put just the right amount of silicone where it needs to go, so we see fewer problems with too much coming out or not enough getting applied. Getting the measurements right saves money in the long run and helps companies meet their green goals too. Many production managers have told me how much difference this makes to their bottom line while also making their operations look better environmentally.

Product quality takes a real leap forward when machines get involved. Take silicone products for example they just last longer and look better too. Modern manufacturing equipment gives companies exact control over how silicone gets applied during production. This means each item coming off the line maintains pretty much the same quality level across the board, which matters a lot for those durability tests most companies run these days. Look at everyday items such as phone covers or oven mitts. When silicone spreads evenly throughout these products, they simply hold up better against daily wear and tear while looking smoother and more professional overall. Customers notice this difference, and it definitely affects their buying decisions in the long run.

Conclusion: The Future of Silicone Dispensing Machines

Silicone dispensing machines stand on the brink of some pretty impressive upgrades, especially when it comes to tech and automation advances. We're seeing all sorts of new developments lately that boost what these machines can do. Take those newer precision nozzles for instance, or the fancy control systems now available that let operators create much more complicated dispensing patterns than ever before. The whole industry seems to be moving this way because manufacturers across different sectors keep asking for products with increasingly detailed designs. Automotive parts, medical devices, even consumer electronics all require tighter tolerances and more precise application methods these days.

Bringing automation and intelligent systems into silicone dispensing represents a major leap forward for manufacturers. Take automated dispensing equipment with built-in PLC controllers as a case in point. These machines cut down on hands-on work during production runs, which means factories can crank out products faster without sacrificing precision. The real game changer comes from the smart features though. With continuous monitoring and instant diagnostic capabilities, these systems catch issues before they become problems, keeping operations running smoothly while maintaining that all important product consistency. Looking ahead, we're seeing silicone dispensing tech become increasingly sophisticated. From automotive assembly lines to medical device manufacturing, companies across industries are finding new ways to integrate these advanced systems into their workflows, pushing production limits further than ever before.

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY